I've been using my Ender 3 for about four months now and it's been working wonderfully. The print quality is amazing and all the prints are very strong. Then about three weeks ago, my entire system crashed while Ultimaker Cura was open and it lost the profile for my 3D printer. I recreated the profile to the best of my ability with other people's working profiles online, but none of them worked right. I've been getting severe under extrusion in all my prints, and they're incredibly fragile. For now, I've just been printing a 1"x1"x1" test cube. I've tried many steps from other people's posts online to fix the problem, including:

Raising the print temperature for PLA to 200 °C.

Checking the extruder for signs of too little tension or too much tension. I checked, and the PLA has light tooth imprints on it, and no grinding or damage to the filament.

Clearing out the extruder. I disassembled the whole extruder assemble, and flushed all the plastic from each part with a heat gun, and metal pick, and then tried reprinting, but it didn't work.

Trying a newer Ultimaker Cura version. At the time, I was using Ultimaker Cura 3.1 and hadn't updated because it was working well. I then tried the newest stable release of Ultimaker Cura 3.6, with a few different profiles, and then I also tried the beta version of Ultimaker Cura 4.0, but none of these worked.

Increasing the extrusion rate. I incrementally increased the extrusion rate from 100 % all the way up to 130 %. The prints looked a little better and were a lot stronger, but this still didn't fix it.

Trying a different slicer. I then downloaded Slic3r and created a new profile in that. The prints turned out a lot better, but there was still significant under extruding.

Checking the filament tube for any burns or damage, and ensuring it's inside the extruder assembly all the way.

If anyone can help me figure out what's going on with my printer, I'd really appreciate it!

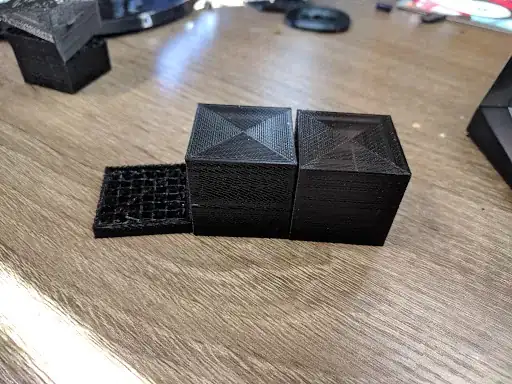

Here are some pictures of the prints I've been getting: These were made in Ultimaker Cura with different small changes to the profile made

These were made in slic3r with a flow rate adjusted up to 130%

These were prints I made before I lost all my settings in Ultimaker Cura.

Here's some of the material I read/watched and checked before posting myself:

- I am experiencing some severe under extrusion

- Sudden underextrusion on Ender3

- r/3DPrinting: Under extrusion on Ender 3

- Fixing a Filament Flow Problem on CR-10 mini, CR-10 or Ender 3 by CHEP

Edit: Here's my printer profile: Ender 3 Profile Google Drive