I did calibrate the extruder to extrude exactly 50/100 mm and it is fine. I have replaced the old (prehistorical) extruder that was giving me the problem with a new one. The issue does not go away. It is severely under extruded. The nozzle is a 0.4 mm, if I extrude manually the extrusion is nice and clean but when printing its a mess. I have the following setting in Slic3:

- Layer height: 0,16

- First layer height: 0,16

- Filament diameter: 2,94

- Extruder temperature: 184°C

- Extrusion multiplier: 1

- Fill density: 15%

In Marlin I have the following setting for the extruder:

- Steps per unit: 1450 (I use micro steps)

- Default acceleration: 3000

- Default retract acceleration: 3000

- Default Ejerk: 5

How can I solve this problem?

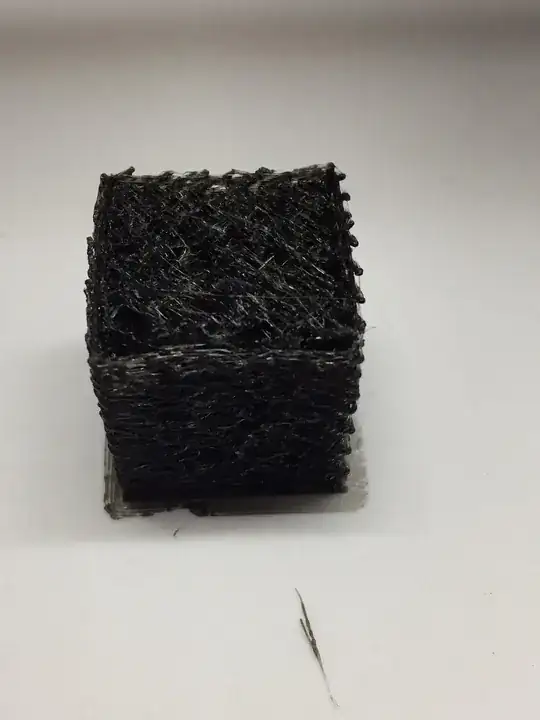

This is a 20 mm cube I stopped after 15 layers!

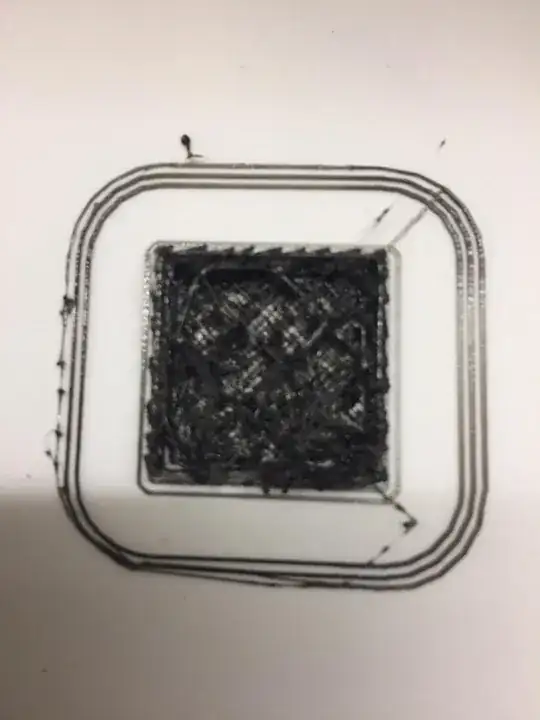

Here is another 20 mm cube, the dimensions are perfect but is absolutely a mess.