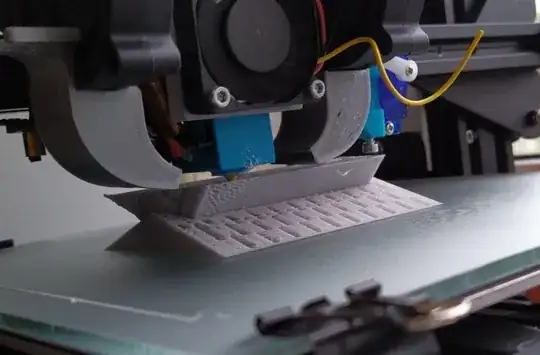

I've recently changed my Ender3's hotend to E3D v6 clone with Titan direct extruder, so I can print faster than on stock. But when I increased the speed up to 70 mm/s for walls and 80 mm/s for infill (PETG, nozzle temperature of 225 °C, bed temperature of 80 °C, 0.2 mm layer height, 0.4 mm layer width), I've faced this kind of issue:

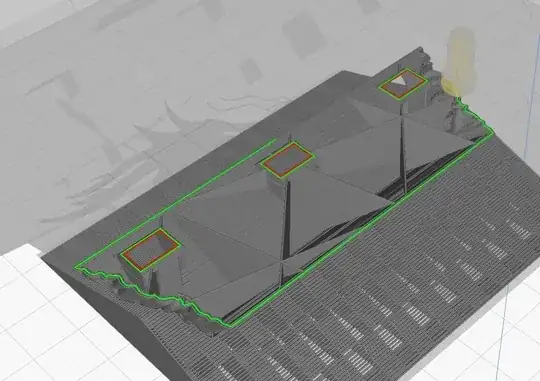

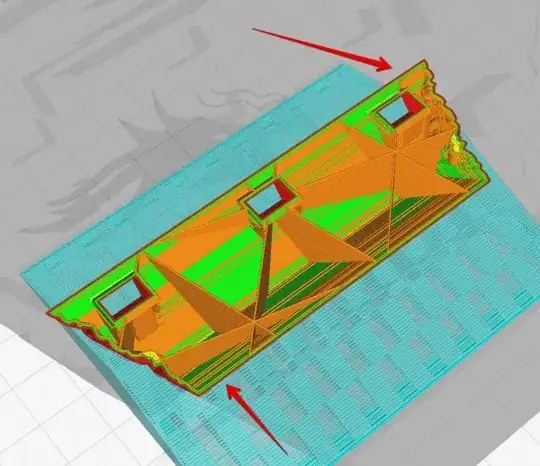

Here's how it looks in Cura:

The printer's head goes from left to right, counter-clockwise and I get issues on both exits from curved shape.

First of all, I thought, it is connected somehow with retraction, but according to Cura, both problem places are in the middle of the current layer. Later I thought it could be related to Linear Advance and disabled it on the next test print, but it did nothing:( Slowing the printer down to 60-65 % in mid print solved the issue, but it's not what I changed the hotend for:)

Maybe someone has any ideas, what's wrong with it?