I work in a teaching hospital and we have a research project we're interested in pursuing. We'd like to 3D Print tubes we'd implant into rats to help with nerve regeneration. We're interested in the shape of the tubes right now, more so than what material it is or whether it's biocompatible etc..

So this question isn't necessarily about what type of plastic or whatever we should print in. My question is more so:

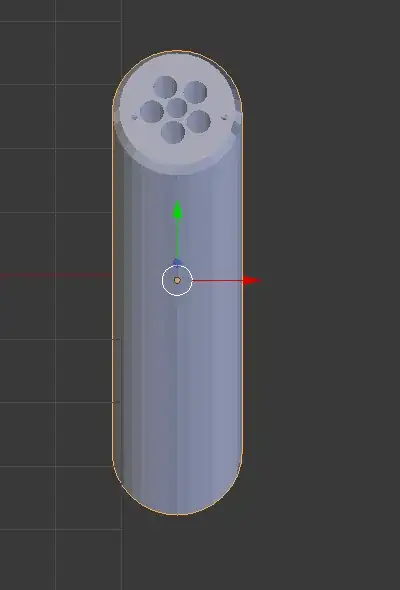

We'd like to print a tube that's 1 mm in diameter, about 1 cm long and has as many micro "tubes" crammed through it as possible, something like this:

I currently have a Stratasys j750 in my lab, a UPrint Se and a Prusa i3 Mk3s. They all work well but for the detail I'm looking for, come up a bit short. They have advertised accuracies of 14 microns (well, the j750) but thats just in the z direction, x and y are more like 200. If I went to get PRECISE, what technology should I look into?