I've got several examples like the image below where the perimeter either doesn't bond to, or doesn't reach the infill. I tried adjusting the infill overlap parameter in Slic3r from its default of 25 % to 30 %, but it doesn't seem to have made a difference. This is on a new Tevo Tornado that's all stock + a Petsfang Bullseye cooler.

Neither speed variations, nor temp variation seems to impact this issue. I'm beginning to suspect that it's related to some sort of play in the Y-axis, as if you look at the defect in the picture, it's the most pronounced running north/south in the picture, which would be layers along the X-axis (meaning their relative position would be impacted by Y-axis movement instability). I'm replacing the leveling springs with PETG standoffs tonight (I have a BLTouch) and will try again then.

I tried 25, 30, and 50 % infill overlap as per a comment request, and that (50 %) seems to have improved another issue where the infill on a first layer would often not reach the perimeter shells.

I tried the following print speeds with all of the following temperatures (nozzle/bed): 190/60 °C, 193/65 °C, 193/70 °C, with 3 perimeters.

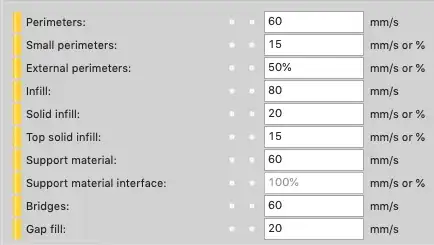

That's default behavior. I've also gone to

- Perimeters - 80 mm/s

- Small perimeters - 20 mm/s

- Infill - 90 mm/s

- Solid infil - 25 mm/s

- Top solid infil - 20 mm/s

- Bridges - 70 mm/s

- Gap fill - 25 mm/s

With no visible change in this outer perimeter behavior (the faster set of numbers is what I print with in general).