What are the best settings for Ultimaker Cura to have support material that's easy to remove for my Anet A8. I have printed an object with two different spools of PLA (same manufacturer just different color). The black print was printed with 200 °C, the grey one with 210 °C both a flow of 100 %. Thee black print seems like it has a little over-extrusion while the grey print has some under-extrusion artifacts despite the higher printing temperature. The grey support was really hard to remove and looks super messy the black one not so much...

What would be better settings?

Could it be that the material is so much different despite same manufacturer? The black one seems to flow much better than the grey one. Both have suggested temperature of 210 °C

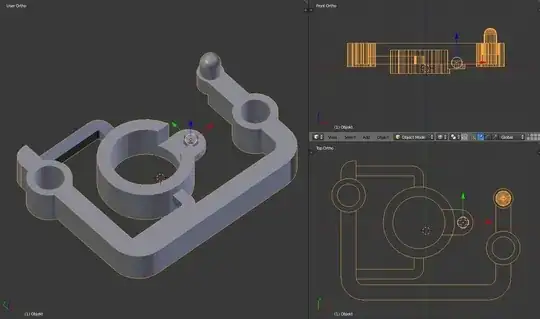

BTW the thing is 33x25 mm in size. It's rather tiny that makes printing it somewhat awkward...

I have finished another print with a brim and a different support setting (Cross with 50 %) and at 195 °C and an infill rate of 100 %. The support came off much better, the under-extrusion is minimal on the layers however for some reason the top layer does get messed up with open spots and the little nob at the corner was just a a mere stringy stumb that fell off instantly and the walls of the holes came out spongy while the layers of the ring and the long side are smooth and fine...