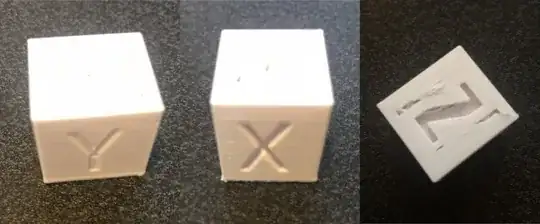

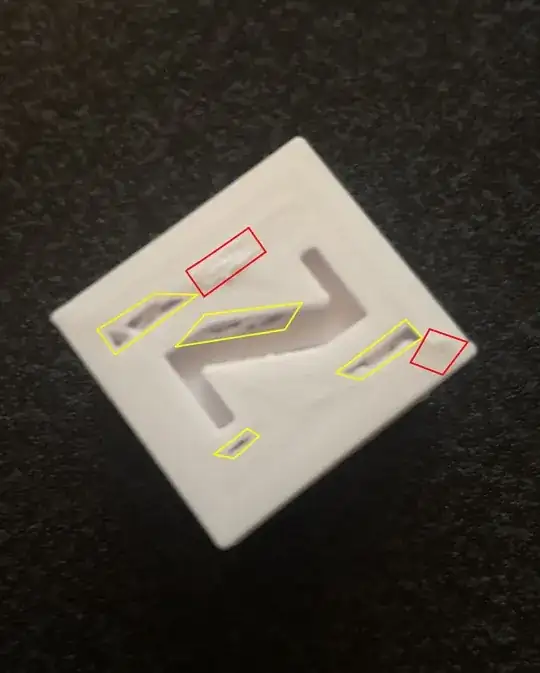

After noticing that my ender 3 couldn't print a 'perfect' circle I decided to use a calibration cube to see if that could be the issue. These were my results:

I did have some successful prints before noticing these problems but it would be great if anyone could help/find a solution.

I think it may be because of the belts tension as I had accidentally over stretched it by putting it over the wheels instead of under: is it worth getting a new belt then?

I use 20% infill, with triangle pattern in cura, using the standard 0.4mm nozzle.

Edit

After doing a different testprint and measuring, it revealed that both had an accurate 20mm Y and Z, but only an 18.5mm X. Might I have destroyed my belt when I mounted it overstrained?

Edit2:

After purchasing a new X belt, the calibration cube was much closer at 19 x 20 x 20. But still not at a good enough tolerance for my liking. Additionally, when printing a cylinder, two relatively flat edges were printed with it either side (perpendicular to the x-axis).