The following rheology question relates to predicting the flow of polymer-based non-newtonian fluids extrusion processes. In this case, applied to 3D printing.

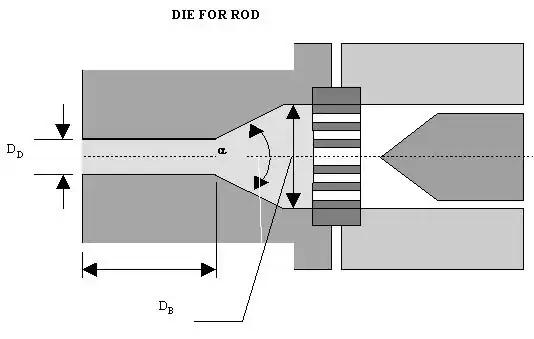

I'm trying to calculate the pressure required to produce the desired output based on my current system (pictured). I'm working under the assumption that it can be described in the same way as an MFI test.

Specifically, is it possible to calculate the Melt Flow Index (MFI) of a polymer under different test conditions (dimensions)?

The MFI test is defined by the following:

- piston radius (change to match my system)

- nozzle radius (change to match my system)

- nozzle length (change to match my system)

- test load (change to match desired output)

Using either the pre-existing MFI rating or the viscosity (or shear rate and shear stress) is it possible for me to define the test load in order to achieve output (gr/min)?

This paper seems to prove this is possible but I've not yet been able to condense it into a single/understandable equation.

Melt Rheology of Polymer Blends from Melt Flow Index (bottom of page 222, 223, 224)

I know that pressure = force / piston cross-sectional area