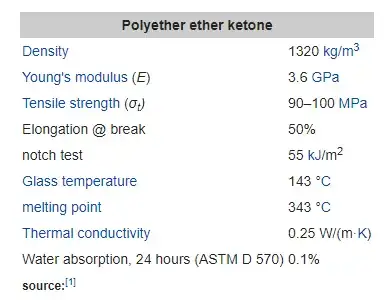

Referring to the table provided in 0scar's answer, the key challenge with high temperature materials is the gap between the glass transition temperature (bed temperature) and the extruder temperature.

Polycarbonate for example is listed as usable up to 121°C, printing on a bed at 80-120°C, but requiring an extruder temperature of 260-310°C. This extruder temperature is potentially going to challenge the mechanical, thermal and measurement properties of a printer.

In this application, you don't strictly require 100°C operation, so Nylon (80-95°C) and ABS (98°C) might be worth trying. Even if one side of the part is at this temperature, immersed in steam, the opposite side is exposed to air and convection cooling. Providing there is sufficient thermal insulation and internal rigidity, the upper shell of the part is likely to support it. However, if the inner face does start to flow it may take some time before a problem is apparent.

So long as the material is not soluble, absorbing moisture may not be a major issue.

When it comes to being food-safe, this is a huge can of worms, and you're really looking to investigate 'how much of a risk' rather than get a go/no-go answer.