Extruder 'clicking' is an audible indicator that the teeth on the hobbed gear are slipping... determining if this is a symptom or a problem is where things get tricky.

Not so sure about adjusting feed rate - as this will impact the entire print and may introduce other problems. Measuring the dimensions of a sample print with a set of calipers is a good way of identifying over/under extrusion.

General maintenance items perhaps?

Thermistor: Nozzle temperature measurement is dependent upon the precision of the thermistor and how well it is attached... 5% drift at 220 degrees may be as low as 210 degrees or as high as 230 degrees. Use a thermocouple on a multimeter, non-contact probe, etc. to verify your nozzle temperature.

Temperature: Nozzle temperature 'sag' of +/- 5 degrees is normal. Monitor nozzle temperature during a print to see if it stays within this range (see: Speed below).

Speed: Printing fast is awesome... when you have a hotend that can keep-up with the demands of melting incoming filament. Too fast, and the filament may not be properly melted; increasing the pressure needed to force it through the nozzle. Support material and infill typically print faster than the rest of the model - you mentioned hearing clicks "...mostly during filling areas."

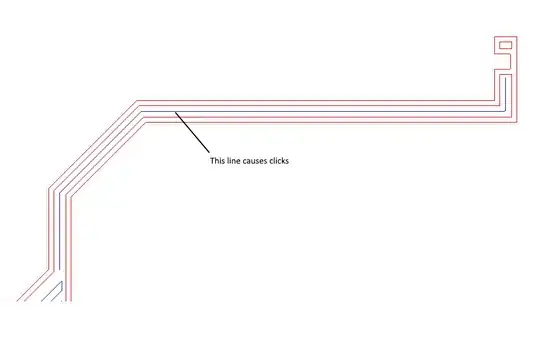

Alignment: Make sure the hobbed gear, idler bearing, and filament are properly aligned. Filament that wanders around in the feed path is much more likely to slip and/or buckle.

Teeth: Make sure that the teeth of the hobbed gear are clean and clear of debris. 'Gunk' in hobbed gear teeth reduce grip on the filament.

Tension: Increase the tension between the hobbed gear and idler bearing if possible; worn hobbed gears may need a little extra help holding-on to the filament.

Stepper: Heat generated by the stepper motor can be passed down to the hobbed gear... softening the filament and causing it to slip. Stepper quality, capacity, and duty cycle can greatly effect how much heat is generated; 200+ degrees is entirely possible. Passive cooling (heatsink) is a good idea, active cooling (fan) is better.

A loose heat-break, nicks in the filament path, variations in filament width, etc. are all possibilities as well.

Also, Simplify3D created a great reference for solutions to common 3D printing problems (if you haven't seen it already).

https://www.simplify3d.com/support/print-quality-troubleshooting/