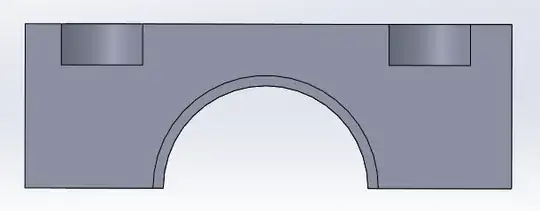

I am designing a part that has to clamp around a 11mm bushing, and due to other design constraints, it has to be printed with a semicircle-shaped overhang:

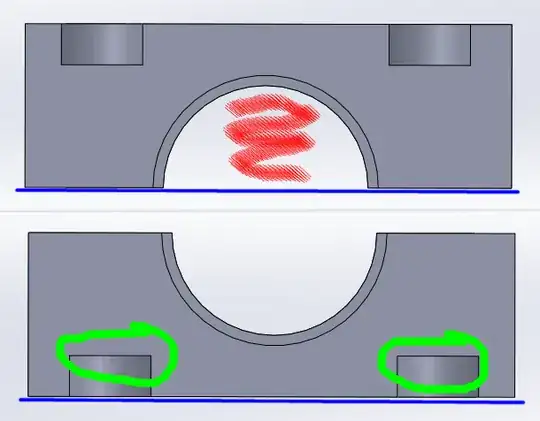

This is proving very challenging to print. Two copies of this part have to clamp tightly around the bushing in all directions. Support material is rather hard to remove from the very top of the arc (where the overhang angle is the highest) and I often end up removing just too little of the support material (so the part doesn't fit around the bushing) or too much (and the bushing can wobble around).

Is there any way I can modify the design of this part (bearing in mind that it absolutely has to be printed in this orientation) to make it more tolerant of my inaccuracy when removing supports, or is there perhaps some way to manually design supports that are easier to remove (Simplify3D and Cura both don't quite cut it)?