I tried using input shaping in Marlin for my coreXY, but it doesn't work correctly.

When printing ringing towers in vase mode (or other things) and setting frequency on M593 other than zero, printed layers won't stack on top of each other about half centimeter shifting every layer. I only use "after layer" G-code for ringing tower, when printing it, the first two layers (of which the frequency is zero) prints normally but after that layer shifts.

I pulled the stepper cables out and manually moved gantry (no perpendicular shift was observed). Then enabled min. frequency and max. step rate in Marlin compiled; RAM and EEPROM usage was about 9-12 percent. I have a Monster 8 printer controller board.

I built my own machine and previously I made a bed slinger with ATMega RAMPS. When I tried input shaping on the bed slinger, similar thing happened and when searched for answer people said ATMega maybe couldn't generate steps as it should and hasn't enough computation power but the Monster 8 uses an ARM processor.

Also, because somehow the Y stepper socket for a stepstick driver won't work, I used external TB6600 for it and DRV8825 on X-axis.

Update

Here the pictures:

I downloaded spectroid app plucked both belts until frequency made the same. Looked at a and b motors added clearance for idlers. Deracked gantry until at front distances be same. There's side to side play when moving back and forth although.

I noticed when printing printer shaking a little, because it is my second experience I didn't know that 12 mm rail 's wagon goes outside 2020 extrusion so didn't put triangle brackets at top also they are mdf, because I had laser cutter and decided later put aluminum ones.

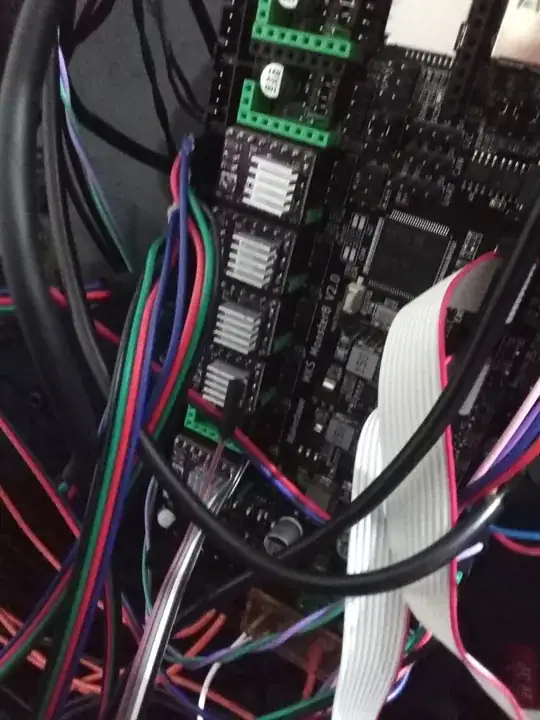

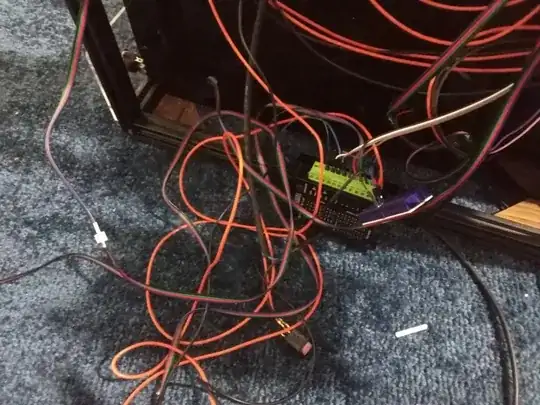

Here is electronics. I didn't connect enable on tb6600 so it is always enable, I don't know if it causes problem or not.