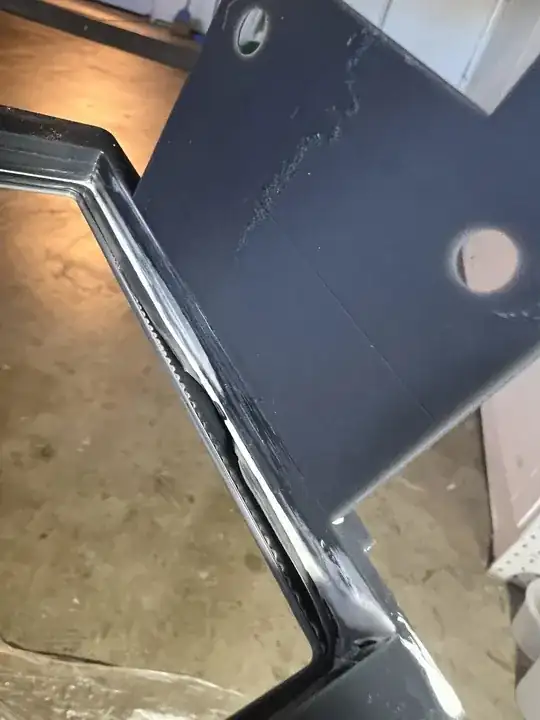

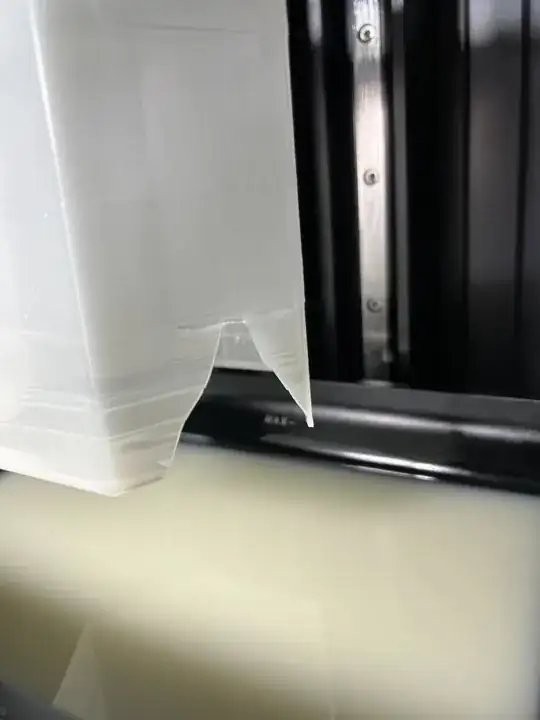

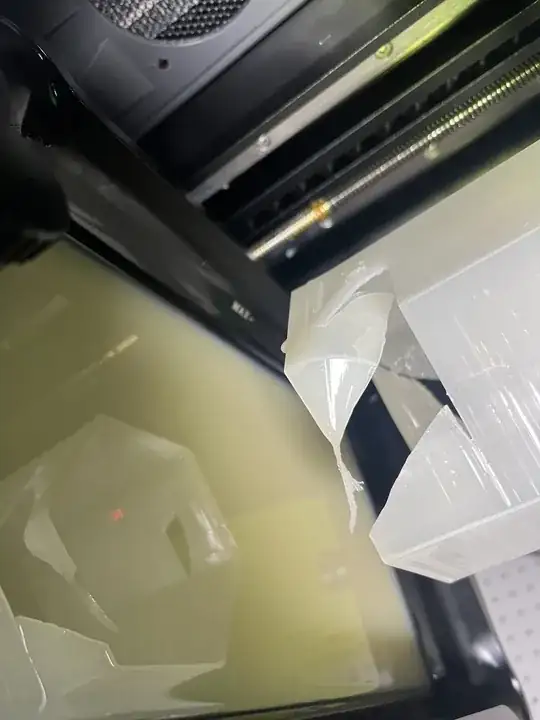

I just recently purchased a Saturn 4 and had a few months of some pretty decent prints. Just recently though, my prints have started to fail due to delamination. I'll attach some photos of the failures.

I've tried increasing the exposure times for both bottom and subsequent layers. I've tried replacing my FEP. I've tried increasing the ambient temperature 24 °C (~75 °F) in the print area. I've tried reorienting the print itself to be more angled and have more supports. None of these yielded much success.

I'm noticing as I go through all the photos I've taken, that there's a lot of Z wobble as my prints are getting farther from the build plate. Not sure if the delamination I'm seeing is related to that but just wanted to throw it on here.

Any help anyone can provide would be greatly appreciated. I'll include all the data I can here regarding my prints. I'm just really disheartened and looking for anything anyone has tried in my situation that yielded results.

I really appreciate any advice.

Printer Settings:

Layer Height: .05 mm

Bottom Layer Count: 5

Exposure Time: 3.5 s (I've tried up to 15 s here as well)

Bottom Exposure Time: 35 s (I've tried 50 s here as well)

Rest Time After Retract: .5 s

Bottom Lift Distance: 3 + 4 mm

Lifting Distance: 3 + 4 mm

Bottom Retract Distance: 5.5 + 1.5 mm

Retract Distance: 5.5 + 1.5 mm

Bottom Life Speed: 65 + 180 mm/min

Lifting Speed: 65 + 180 mm/min

Bottom Retract Speed: 180 + 65 mm/min

Retract Speed: 180 + 65 mm/min

For the head unit mount print, I was using Elegoo ABS-Like Black Resin. For the tulipa, I was using a mixture of Sunlu white resin and Elegoo ABS-Like Translucent Resin.