I own a Creality Ender 5 Plus printer, and I use 1.75 mm PLA filament made by ESUN.

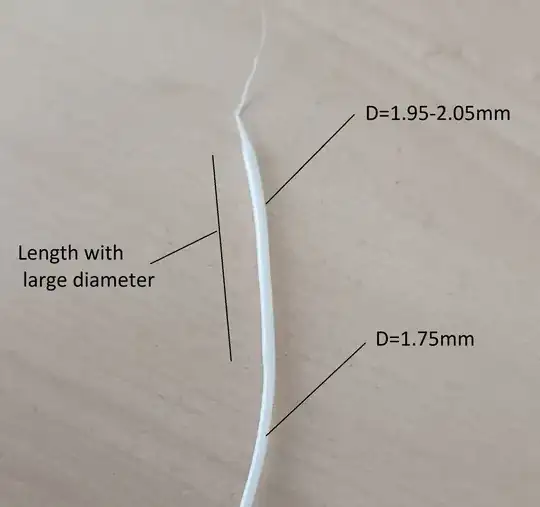

When I print parts weighing less than 200 grams within a day using the standard quality settings (0.2 mm layer height and nozzle temperature of 210 °C), everything works fine. However, when I print larger and more time-consuming parts with the same settings, the filament diameter near the nozzle increases, causing issues like filament jams.

This problem is particularly noticeable when printing lightweight parts at high resolutions (e.g., 0.12 mm). How can I address this issue?"