1.Active chamber heating (fan forced convection +heating bed +PTC heater) vs 2.Passive chamber heating(natural convection+ heating bed)

In the book "3D Printing Failures_ 2020 Edition_ How to Diagnose and Repair ALL Desktop 3D Printing Issues" writen by Aranda, Sean, it is said less cooling rate could let polymer have more temperature and time to release stress. This is the reason why chamber heating is used. But

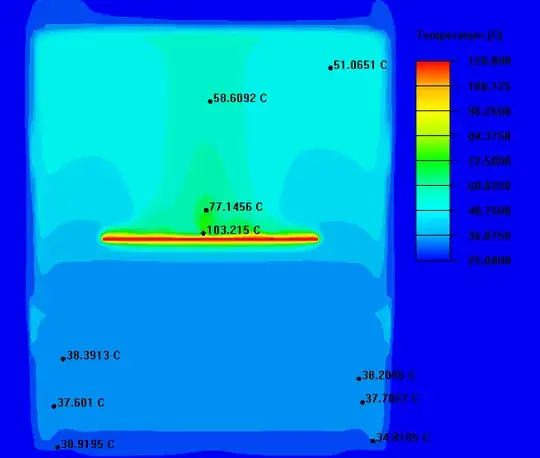

- In the design 1 chamber above bed is already >50℃ with 120℃ heating bed.

- In another design "120℃ bed with PTC supplyment which is cycled by a fan and the chamber can be up to >60℃". It forms forced convection, so the printed part may be cooled quickly even though the chamber has up to 60℃ temperature(the temperature difference between printed layer and ambient changes slightly).

So why we use chamber heating with fan forced convection design other than natural convection deign?

- Printed material: ABS

- Bed temperature: 120℃