Setup: Anycubic Kobra Neo (Firmware v1.3.3), Cura 5.2.1

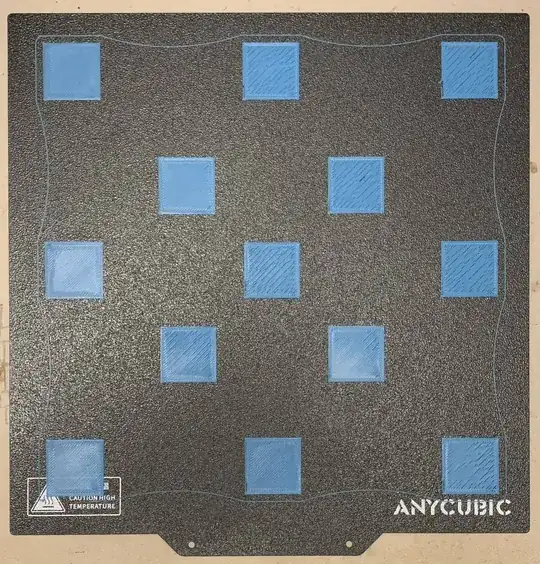

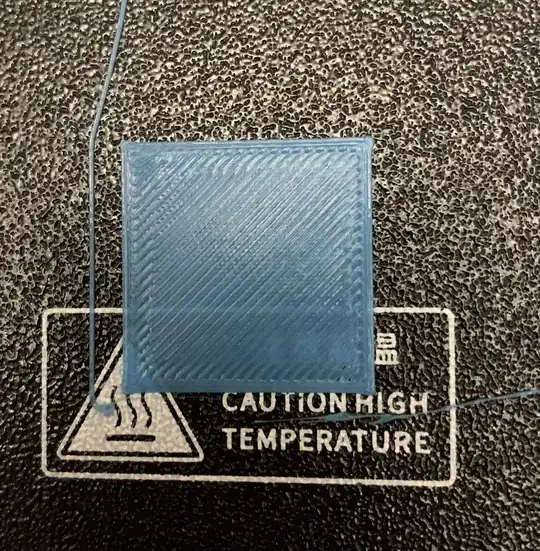

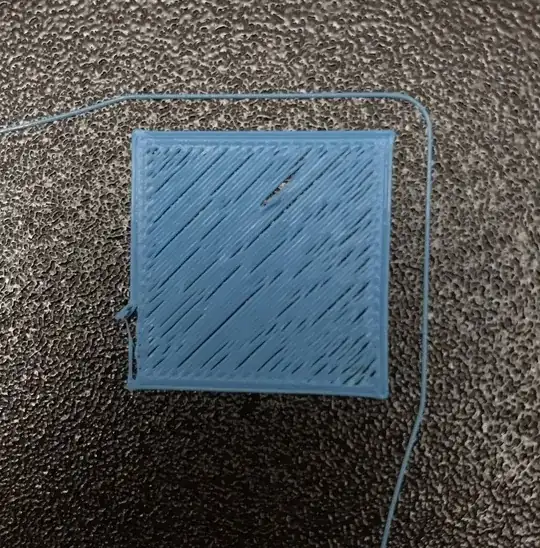

I recently bought an Anycubic Kobra Neo. It works but has issues with auto bed leveling. Specifically, auto bed leveling does not compensate for bed tilt in X and Y directions correctly. After running the auto leveling, the printer consistently prints higher up in the right back corner, compared to the front left corner of the build plate.

The problem does not seem to be related to auto bed leveling being disabled though. While printing, you can see the Z lead screw turning, so the printer definitely tries to compensate for something.

What I tried:

- Print Z calibration patterns

- Run auto leveling again using the attached controller

- Run auto leveling again with the

G29command and priorG28to home, followed byM500to save the mesh - Add

M420 S1to start G-code (also triedM420 Land both together) - Reset EEPROM with

M502 - Use Repetier Host instead of Cura

- Used different filament