I am currently working through various different iterations ofccreating a propeller for a model ICE (nitro engine). So far I have managed to disintegrate each of them eventually. I have been experimenting mostly with PLA and PETG so far. I am currently thinking about using carbon-infused PLA or using PC (I found one that is printable on my printer). However, I am not so sure what properties I exactly have to look for when it comes to a propeller.

I am making the following assumptions:

- When rotating fast (5-6k RPM) there it probably has to create quite some centripetal force and I assume this would translate to tensile strength

- When the engine starts or stops it gets accelerated and decelerated almost instantly which probably causes quite some jerk to the propeller. However, I do not know what property that would translate to, also tensile strength.

So far the PLA propeller has held up the longest and I cannot rule out that it accidentally touched something when it broke. That is of course something it does not have to be able to handle, so I am probably going to give PLA another chance.

The PETG propellers all literally broke apart the second the engine started, and it did not even hold up one rotation.

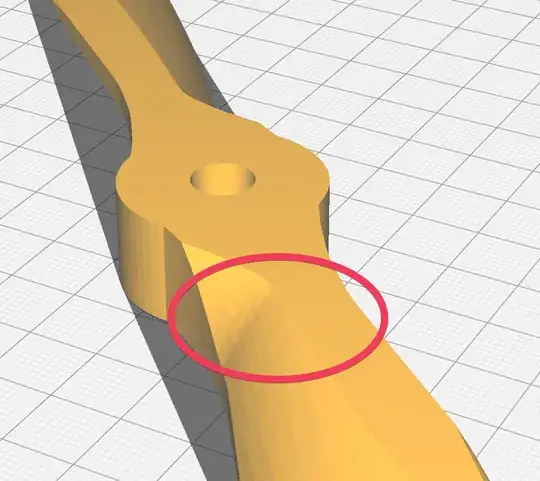

The design of the propeller is actually sacrificing some aerodynamic efficiency in order to make sure there are no "thin" parts. It is typically breaking in the section I have highlighted in the the following picture.

I have also a picture of the "remains" of the broken PLA propeller. It actually held up many runs before it eventually broke. It actually partially delaminated the entire wall.

I am looking for two recommendations/tips:

- What material properties should I look for in my use case?

- Less important, but some tips regarding print settings are also appreciated. So far I could notice that smaller layer size helps, and thicker walls also helped.