I printed this Curvy vase from Thingiverse and it came out pretty well on my Chiron.

However, I am not happy with the Z-seam that is very large. When I look at other people's problems with this, they often seem to have too little filament at the seam, but I have too much. What setting should I change to make it less visible?

- Printer: Anycubic Chiron with Marlin 2.0.7

- Material: PLA

- Slicer: Cura 4.8.0.

- Nozzle: 0.4 mm

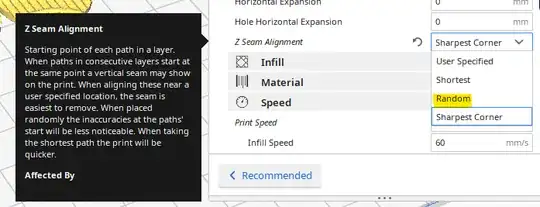

All Cura settings are here (except that I lowered printing temperature to 200 ºC while printing).

All files used and some pictures are here.

2021-03-07 Addendum after I made 19 test-prints of a small portion of the vase's neck. Below are some of my notes:

- Combing Mode=All is better than Off

- Speed=60 is worse than 40

- Retract Before Outer Wall=On is worse than Off

- Outer Wall Line Width 0.45 to 0.35 gave a Z-seam on the outside with more build-up

- Inner Wall(s) Line Width 0.45 to 0.35. Some places has less contact between layers, so less appealing and less robust. Also less material use.

- Outer Wall Wipe Distance 2.0 spread ot the seam (too much), and also made a ditch before the Z-seam (on the outside of the ring).

- Coasting tripled to Vol=0.588 and Wipe Distance 5.0 is more appealing. Two changes at once make it impossible to know which one helped. 5 mm is not enough to completely wipe.

- 50% printing speed improved Z-seam and surface smoothness

In the future I will use slower speed for Outer Walls, test Wipe distance=2*Line Width, use Combing (turned Off because of some advice to do so when LIN_ADVANCE is used) and experiment with faster retractions and Z-movement. Pictures and complete notes are available here.