Before I start, I'll give you my setup:

- Ender 3 Pro

- Marlin 2.0.7.2

- Material/Nozzle: PETG 0.4 mm @ 215 °C

- Bed: Glass @ 80 °C

- Default printing speed: 70 mm/s

- Standard part cooling fan

Since I've updated the Marlin FW on from factory default to 2.0.7.2, my printer stops printing and gives out an thermal runaway exception message. Note that, after the firmware flash, I performed a PID-Tune multiple times.

The problem is absolutely repeatable and happens always on beginning of layer 2 (more precisely: 40 seconds after beginning layer 2). Changing PID values doesn't change anything to the moment of the error occurring.

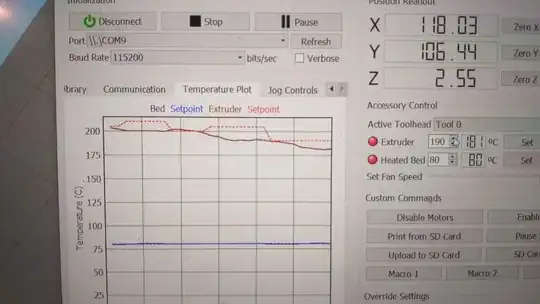

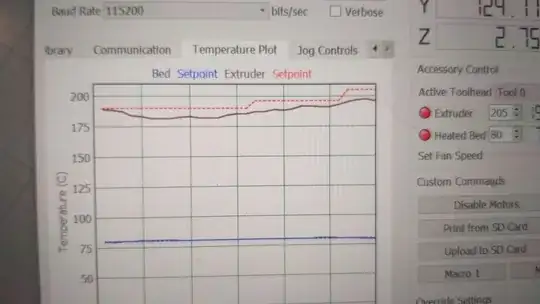

I managed to run it longer by repeatedly dropping the temperature set-point and making a photo of the temperature plot. First photo is right after the initial drop from 215 to 205 °C. Second is when the temperature started rising slowly again.

After this temperature drop, the hotend temperature seemed to be much less stable and reached only 205 °C.

At Layer 12, the same thing happened again. But dropping the temperature far too low for PETG and having the "same" issue again, making me stop the print.

This problem is pretty urgent and I haven't found any suitable solution by now. Do you have any ideas of what may cause this trouble? New heaters and thermistors are on their way right now. But I fear that this is not a hardware problem since none of the components are damaged and dysfunctional, nor the moment of failure is random.