I'm pretty new in the 3D printing world, and there are some doubts that have come my way and I've not been able to find anywhere.

Usually, I'm going to try to print pieces bigger than the bed of my Elegoo Mars Pro (which is 115 x 65 x 150 mm, so it's pretty small). Everywhere I try to look at this they are talking about Fused Filament Fabrication (FFF) printers, and I guess that material will make the answer to these questions to be different, that's why I'm asking here. All of these questions are focused on SLA printers.

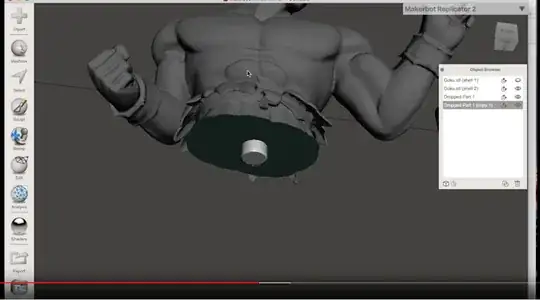

Is there any kind of technique / slicer software to be able to print those pieces by parts?

I've read about slicers, but there seem to be a bunch of them, and some of them work best with some printers than others, and have different features but I haven't seen any that helps in this matter.

Also, I've seen the typical plane cut, but this doesn't make it easy later on to "fit" pieces. I would need some kind of female - male joint. Is there any (free) slicer that helps in that, and makes those joints to be accurate and solid?

Thank you!

I removed the "shrink size" part in the question and published it as a separate question. Also moved to a different question "gluing separate pieces" part.*