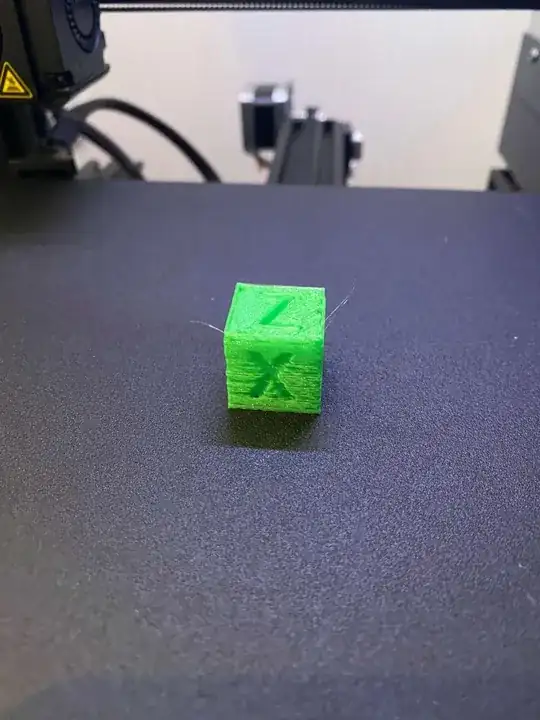

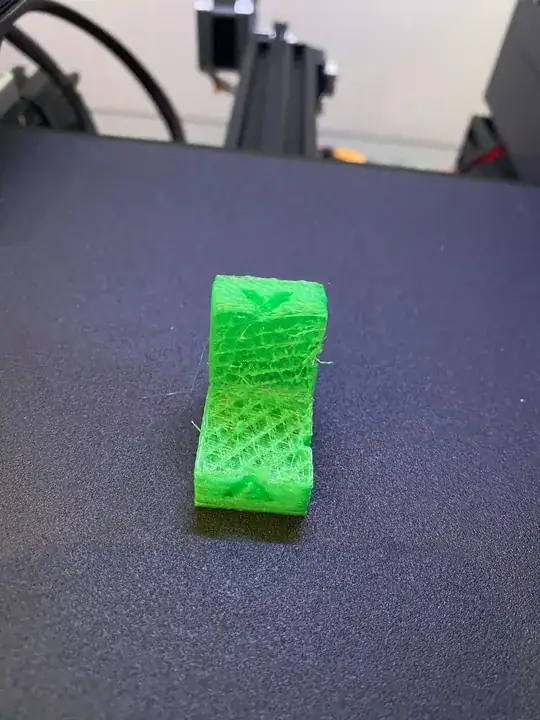

I recently bought some SUNLU PLA black filament and was attempting a small print with it and it started to come out in strings and lumps and was incredibly inconsistent. Before this I'd been using some Eryone PLA and those prints were superb, been printing back to back successfully but after using the SUNLU all of my prints since have been having layer separation issues. I've cleaned the extruder, taken off the fan and cleared out the hotend of some wisps of filament, then flushed it through with some more reliable filament which looked better and replaced my magnetic bed sticker with a new one as the adhesion on the initial layer was poor even though the bed looked level. Once I replaced the sticker, the adhesion on the first layer is excellent. I thought I'd fixed the problems so tried an XYZ cube and still getting serious layering issues and the infill is thin. Any ideas what else I could do to fix this problem? I've put slicer settings below:

- Hot end temp: 210 °C

- Bed temp: 60 °C

- Fan speed: 100 %

- Print speed: 50 mm/s

No custom modifications to the standard Cura profile for the Ender 3.

My filament diameter setting in Cura is 1.75 mm and so is my filament.