I own an older Anet A6. Flashed the Marlin Firmware on it (and think I configured it properly). Also updated to the latest 2.0.5.3 some days ago). The nozzle is a 0.4 mm one, direct drive extruder.

When printing calibration cubes I used

#define DEFAULT_AXIS_STEPS_PER_UNIT { 99.7, 96.4, 400, 91.6 }

settings to correct for what I measured earlier. So the printed cube 20x20x20 mm came out almost "perfect". Yet I faced another problem: scaling. So printing stuff 100 mm wide resulted in 97.2 mm prints. As if an error multiplied with the distance.

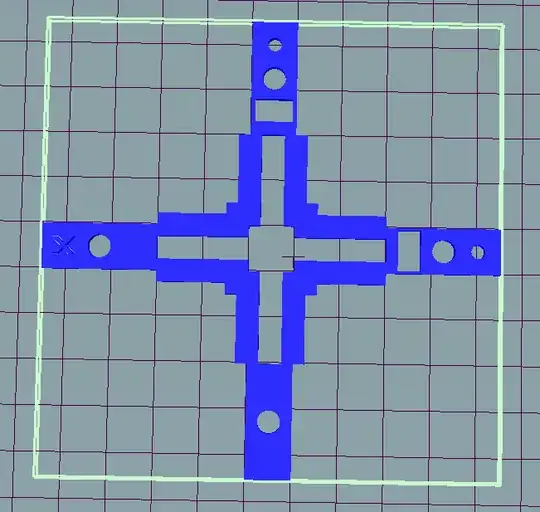

So I created a test object consisting of multiple "rectangles" (overlayed) in X and Y direction. Some of the dimensions were less than required and others bigger. .

.

So the holes ("drills") were 0.4 mm too small (so half a nozzle diameter). In "Cura" I could fix that with the newly added inner hole correction or negative horizontal expansion values. Yet this would also "cut" the thin parts (top and right rectangle on the image - with a width of 1.2 mm - so 3 lanes of print material on my 0.4 mm nozzle).

Without and with adjustment the inner width of the rectangles is also off by more than 0.2 mm.

I printed with my normal speeds (80 mm/s for fill and even slower for other stuff) which creates fine output except the accuracy. I also printed at 20 % of this speed (so <10 mm/s for the first layer!) without any change. So it should not be the "acceleration/jerk" creating the issues.

I then restarted calibrating everything:

calibrated extruder (10 cm filament ... and measuring how much was really moved), was not off by more than 1 mm

calibrated axis by moving nozzle to a specific point and measuring X/Y/Z movement ... I needed to go back to 99.9 for X, 99.9 for Y and 101 for Z). So almost back to vendor settings.

I moved the hotend over and over - replicated the exact movement in all directions 20 times each. It did not "slide", so stuff started and ended exactly at the same spot each time.

Now I printed my test cross (and other stuff) and while the X-Axis was only a bit off "outside" (inside still a bit more off), the Y-Axis was only 97 % and height as it should.

I printed via:

- RepetierHost 2.1.6

- Cura 4.6.1

- RepetierHost 2.1.6 + Cura exported gcode file and adjusted "speed" (25 % of Cura-settings)

Sum up:

calibrated extruder (10 cm filament measurement), calibrated axis (measured movement distance)

printed at very slow speed to avoid "acceleration/jerk"-inaccuracy (did it do that?)

prints are inaccurate yet precise (multiple prints result in same incorrect output)

calibrating "steps per unit" via calibration cube results in perfect calibration cubes but still "too small inner holes" and inaccurate prints of bigger dimensions

So: how to properly fix that issue? How to calibrate the dimension accuracy properly - is there something more than "steps per unit" to adjust?

Tried to find an answer here and elsewhere on the internet but seems I lack the right term to search for to find an answer. Hope you could help me.