I'm looking to increase the printing speed, through increasing the volumetric flow rate, which is currently at 5 mm³/s. Larger amounts cause the feeding mechanism to skip steps.

I'm running at 190 °C, which helps with easier bridging less stringing and personally see no reason to increase the temperature to the popular 205 °C.

So, my thought process is the following: since I run at lesser temperature, there is still potential for the heating block to provide more heat and I need a longer nozzle to accumulate more heat and provide more surface area for transfer to the fillament (PLA), to speed up the melting of the plastic inside the nozzle (which seems to be the bottleneck).

That's similar to using larger tips for soldring iron, when faced with heating up large surfaces in order to desolder something large, since we need to stay at precise temperature, and need to increase the heat supply as well.

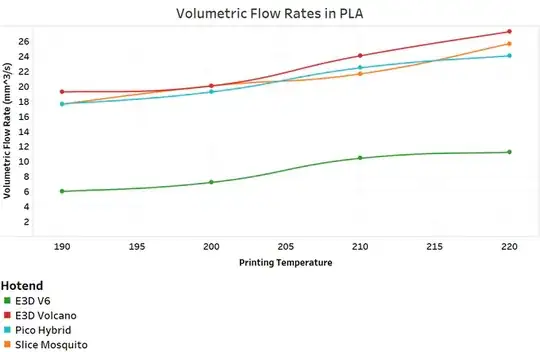

The suggested solution is to switch to the E3D's Volcano "everything included" kit. Which is nice and cool, but I don't think it's that necessary.

- Is it possible to just switch to a volcano nozzle? (Manufacturer#: VOLCANO-NOZZLE-175-0400)

- Would it actually noticeably help to increase the extrusion speed?

Current setup:

- Ender 3 Pro, no mods

- Classic 0.4 mm nozzle