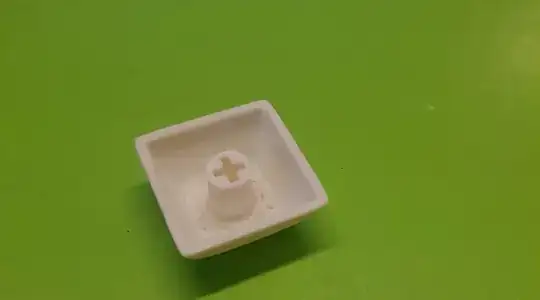

My model is a keycap for mechanical keyboards. There is the cap itself, and a stem with a hole in the form of a cross, which fits the switches themselves.

I print in the same position as it is intended to be used, top up. This means that the stem and the cap are not connected until quite a few print layers.

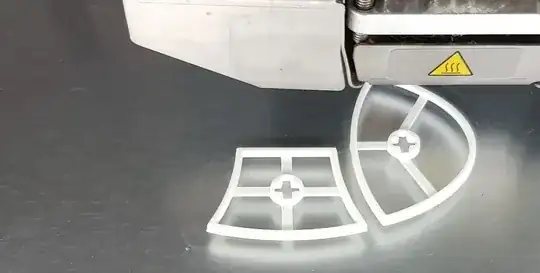

To prevent the stem from falling off during the print (it has a small footprint), I created connectors in the first layers, to hold it in place.

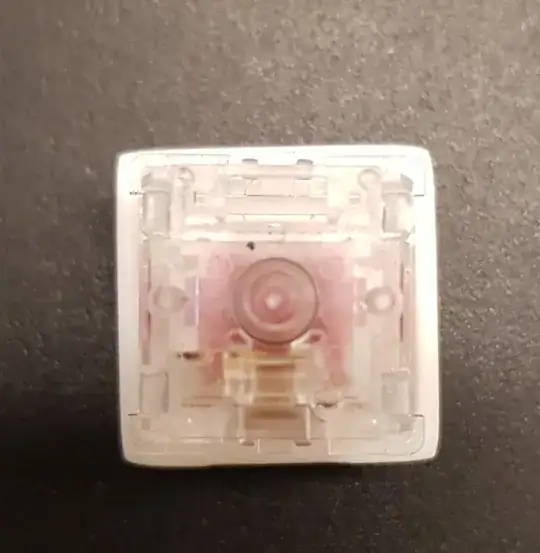

The issue: it seems like all my prints have a rotation of the stem, compared to the cap. It probably rather is the cross-shaped hole, or its walls, that are not completely symmetrical. I do not think it is only the edges against the printing bed that are the cause, since I have trimmed them with a scalpel. The rotation is always in the same direction.

The twist is detectable when watching the keycap with the switch, and more so with keycaps on switches on a keyboard plate (you can see that the edges of the caps do not align. They do in my CAD program):

I use Cura as my slicer, layer height 0.06 mm, and ABS. I attempted a slow print (30 mm/s), which didn't help.

The first work-around that comes to mind is to measure the twist and compensate for that in my model. But I believe that since the problem is in the printing process, the problem would best be solved in the slicer.

What could possibly be the issue? Is there an option is Cura to compensate for this? Short of the work-around mentioned above, what are other steps I should look into?