The shearing strength characteristics, or better known as interlaminar shear strength (ILSS) characteristics, describe the shear strength between the layers. This is also known as flexural or bending strength characteristics. These are best obtained by performing a 3- or 4-point bending test; these tests are standardized by the American Society for Testing and Materials, ASTM International (e.g. ASTM D 7264).

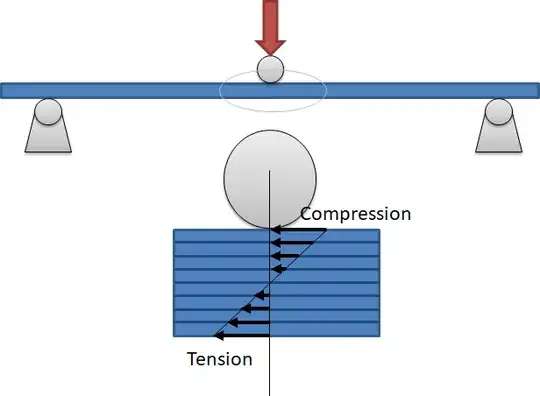

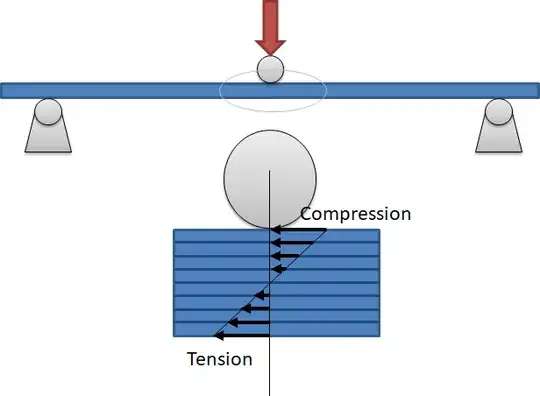

The bending test will cause internal compression (concave side during testing) and internal tension stresses (convex side during testing). The figure below shows the general setup of a 3-point bending test and below that magnification of the stresses inside the test specimen.

The tests concern the interlaminar shearing of layers, so, the much more material a layer consists of (e.g. infill percentage) the higher the resistance against shearing off. Also, how the infill is internally supported by its form helps, if it buckles easily on the compression side, the buckling occurs before shear off.

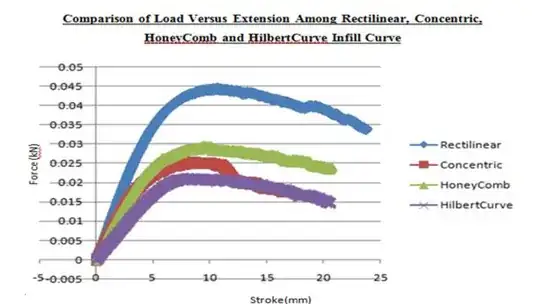

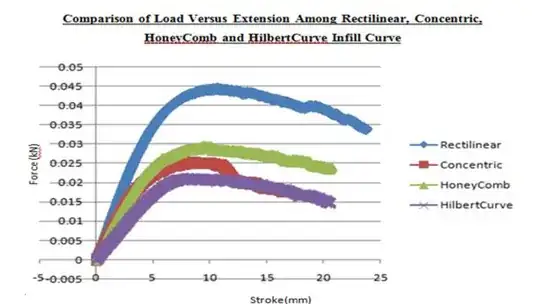

Not only the type and percentage of infill is important for the flexural strength, but also the layer height, nozzle diameter print temperature as found in this research paper. Another paper, "Effect of infill on tensile and flexural strength of 3D printed PLA parts" directly answers your question, quoting the figure from the paper:

You should choose an infill that has the most support. Since year and day, in creating composite sandwich panels (often used in aerospace applications where high stiffness and low weight are essential) honeycomb core structures are used as these honeycomb structures allow minimization of the amount of weight and used material. From the figure above you see that rectangular infill is best suited for FFF products. Honeycomb is the second best, but significantly lower. Note that orientation is key! E.g. this test conducted by Martin shows that Gyroid and honeycomb infill performs better than rectilinear:

To answer your question, not only infill pattern, but also infill density, nozzle diameter, layer height and orientation play an important role in the shearing strength. This is why ASTM has defined a standard so that we can compare results amongst different materials or different lay- or set-ups. These tests are typically performed dynamically (alternating load), statically with increasing load (increasing load with time) or statically fixed load (constant load to determine the creep properties, these test typically take a long time when the load is low).