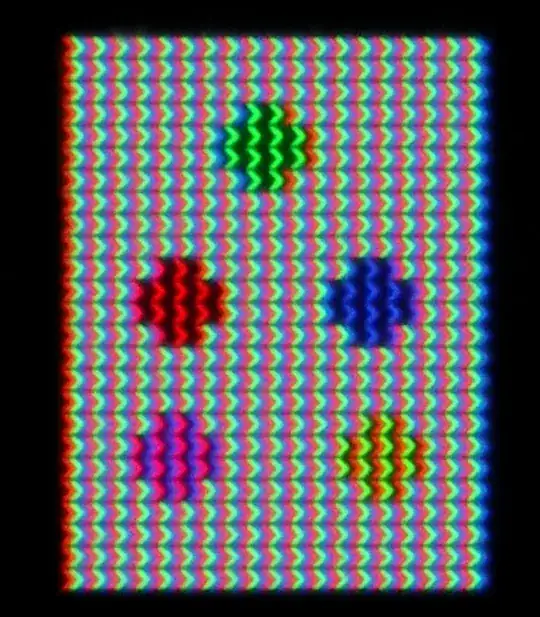

The LCD resin printers I've looked at have pretty standard resolutions like for a smartphone and I understand they use the same technology. However, color LCD screens have three RGB sub-pixels for each color pixel. Check for example this magnified picture of an S-IPS LCD screen:

It seems like they could just omit the color filter and have three grayscale pixels for each color pixel.

It seems like they could just omit the color filter and have three grayscale pixels for each color pixel.

3D printing just uses one color - UV. So why don't they have resolutions that are multiples of three of the usual resolutions?

All results about sub-pixels that I could find are about anti-aliasing, which is different (using the existing pixels better vs. having more pixels).