It is hard to find some measurements on the Ender 3 Max Neo to help you out, but, with the help of question How to calculate linear Y rod length for a larger replacement bed? and some videos on the Ender 3 Max Neo we should be able to come up with the space needed in the back and front.

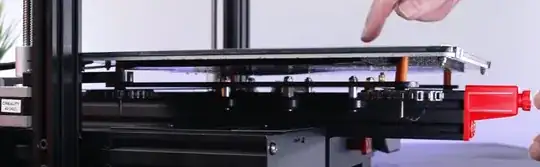

The Y-axis carriage has 6 V-slot rollers running on a 4040 aluminum extrusion profile:

When you know the pitch between the rollers (you need the distance between the first and the last roller) and the diameter of the wheels, you will be able to calculate the overhang of heated bed. Since I have no access to this printer I cannot measure this, but we can make some engineering "guestimations".

From the image above you can deduce that about one third of the bed "overhangs" (beware of the perspective!).

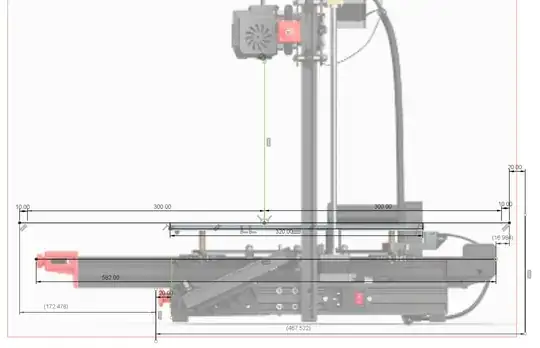

Similarly, you can calculate the length of the Y-axis tensioner to be about 55 mm extending in front of the 4040 extrusion; this implies the bed extends about 80 mm in front of the tensioner.

The back has a NEMA 17 stepper of 42 mm, so an overhang of 90 mm.

This implies that the table should at least be 582 mm + 80 mm + 90 mm = 752 mm deep to fit the bed within the table dimension. At the back you need some space for the bed to reach the home position (when the table has a wall behind it), but you can have the printer extending the bed at the front over the table.