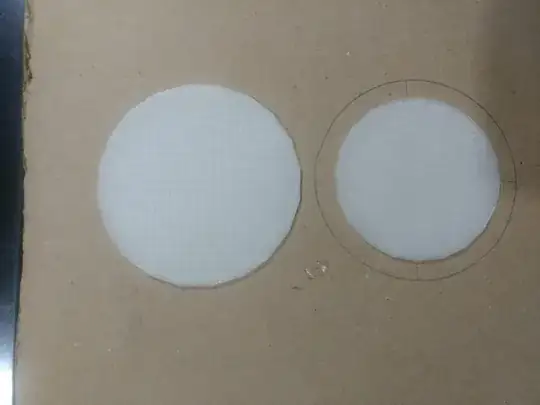

Let's do the math, you printed something of size 9 cm and got a size of 7 cm. This implies that the scale equals $\frac{7}{9}=0.778$. In order to print it at the correct size, you should have printed the object at scale $\frac{1}{0.778}=1.286$; so 28.6 % bigger, i.e. $1.286\times9=11.6$ cm. You printed at 11 cm, so the print should become smaller than the pencil drawn circle on the paper. This is actually what you see in the image you supplied.

This can imply 2 things, you either scale the prints incorrectly to export to stl (but that is unlikely because the Z height is correct), or the steps per mm are incorrectly set in the firmware of your printer. The rotation of the steppers (usually 200 steps) need to be translated into linear movement; this depends on the used pulleys mounted on the steppers (typically used pulleys are: 16 or 20 teeth for belt driven X and Y axes).

Calibrating the steps per mm of the extruder is answered in this answer. For the X and Y axis this works the same. If you have a Marlin based printer firmware, send G-code M503 to the printer over a terminal interface as e.g. OctoPrint, Pronterface (as part from Printrun: 3D printing host suite), Repetier-Host have, you can obtain the current values from the reply; these are listed under M92.

That value for X and Y needs to be multiplied by 1.286 (as an example) to get the correct dimensions. You do this by sending G-code M92 like M92 X100.00 Y100.00 (see this answer that explains which values you should use based on pulleys you use, either 80 or 100) to the printer, to keep these values they need to be stored in memory using G-code M500 (note that the values 100.00 should be replaced by the values you get by multiplying the return values for X and Y from M503 by the 1.286 multiplication factor, only if the error is systematically increasing with print dimensions, otherwise stick to the calculated values from e.g. the Prusa belt calculator).

Without the proper steps per mm, you will not be able to use the full potential of the bed. An alternative as scaling your prints by the appropriate scaling factor will only help if your scaled print is smaller than the bed size divided by that scaling factor, so no use of the full bed. Rather fix the firmware to fit the actual mechanical layout.